Welcome to program 145 of Shortwave Radiogram. I'm Kim Andrew Elliott in Arlington, Virginia USA. Here is the lineup for today's program, in modes as noted: 1:48 MFSK32: Program preview (now) 2:59 Olivia 16-1000: Hams to help develop low cost ventilator 9:42 MFSK64: Ford helps produce respiratory equipment* 14:29 This week's images* 28:00 MFSK32: Closing announcements * with image(s) Please send reception reports to radiogram@verizon.net And visit http://swradiogram.net Twitter: @SWRadiogram Shortwave Radiogram now changes to Olivia 16-1000 ... Before RSID: <<2020-03-29T08:03Z MFSK-32 @ 1422100+1504>> This is Shortwave Radiogram in Olivia 16-1000 ... From ARRL.org: Radio Amateurs Team Up to Help University Design Low-Cost Ventilator 23 March 2020 Amateur radio volunteers from around the world have volunteered to assist University of Florida Professor Sam Lampotang and his engineering team in their quest to rapidly develop an open-source, low-cost patient ventilator that can be built anywhere from such commonly available components as PVC pipe and lawn-sprinkler valves. The amateur radio volunteers are developing Arduino-based control software that will set the respiratory rate and other key parameters in treating critically ill coronavirus victims. Multiple volunteers responding to a call for help from Gordon Gibby, MD, KX4Z, included noted software developer Jack Purdum, W8TEE, and uBITX transceiver maker Ashhar Farhan, VU2ESE. University of Florida physicians are working to address the critical legal aspects as the design moves closer to fruition. The ventilator's valves would precisely time compressed oxygen flow into patient breathing circuits under Arduino control, allowing exhausted patients with "stiff" lungs impacted by viral pneumonia to survive until their body can clear the infection. The software design team is also adding simple features suc, enntilator Changing to MFSK64 ... Before RSID: <<2020-03-29T08:09Z OL 16-1K @ 1422100+1499>> This is Shortwave Radiogram in MFSK64 Please send your reception report to radiogram@verizon.net From New Atlas: Ford uses manufacturing muscle and F-150 parts in coronavirus battle C.C. Weiss 24 March 2020 With auto production at a virtual standstill throughout North America, automakers are repurposing their vast manufacturing resources toward helping fill the shortage of medical supplies around the continent. Ford is partnering with 3M and GE Healthcare to rapidly up the production of respiratory equipment, creating parts and new designs with 3D printing and off-the-shelf auto components like F-150 seat-cooling hardware. ord and 3M are working together to quickly increase production capacity of powered air-purifying respirators (PAPRs), with engineers from both companies actively collaborating on a new-generation PAPR that can be manufactured efficiently with available components. Both 3M and Ford have mined their warehouses for useful parts, using 3M HEPA filters and portable tool batteries, in addition to Ford F-150 seat-cooling components, to piece together the new design. If successful, Ford could handle manufacturing of the new respirator at one of its Michigan facilities, increasing 3M's production capacity as much as tenfold. "We have empowered our teams of engineers and designers to be scrappy and creative to quickly help scale up production of this vital equipment," says Jim Hackett, Ford president and CEO. 3M's traditional powered respirators rely on a waist-mounted, battery-powered blower system to circulate clean, filtered air into a hood, protecting the wearer from airborne contaminants. The COVID-19 pandemic has resulted in a skyrocketing demand for these PAPRs from the likes of first responders and healthcare workers, leaving 3M to look outside company walls to meet the ballooning need. "We're exploring all available opportunities to further expand 3M's capacity and get healthcare supplies as quickly as possible to where they're needed most, which includes partnering with other great companies like Ford," says Mike Roman, 3M chairman of the board and CEO. 3M says that it has already doubled its global output of N95 respirators, producing them at a rate of nearly 100 million per month. Of the 35 million it's making each month in the US, 90 percent are earmarked for healthcare workers, with the other 10 percent going to other critical industries, including food supply, energy and pharmaceuticals. Ford is also in the process of building and testing protective face shields. Designed to be used by healthcare professionals in conjunction with N95 respirators, the transparent shields protect the eyes and face from contact with liquids. More than 1,000 of the face shields will be put into testing at Detroit-area hospitals this week, and Ford plans to ramp up manufacturing to 100,000 per week. Ford is also cooperating with GE Healthcare on building a simplified version of the company's ventilators, used to support patients with respiratory failure or difficulty breathing. Finally, it is using the 3D-printing capabilities of its Advanced Manufacturing Center to create components and subassemblies of other personal protective equipment. Ford is not the only American Big 3 automaker involved in such work. etG tne Motors and Fiat Chr4²er announced their own efforts this week. FCA is prepaee eo m tayuNN manufacturing anOŠde›tZZyjmillion per month. The masks will go to police, EMTs, firefighters, and hospital and clinic workers in the US, Canada and Mexico. Meanwhile, GM is working with Ventec Life Systems to scale up the production of the company's ventilators. Sources: Ford, 3M https://newatlas.com/automotive/ford-manufacturing-muscle-f-150-parts-coronavirus-battle/

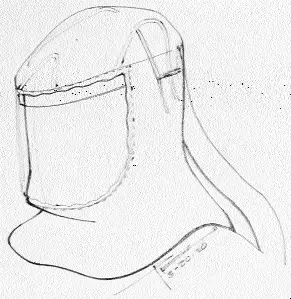

Figure 1. Ford sketch of a disposable hood. From https://newatlas.com/automotive/ford-manufacturing-muscle-f-150-parts-coronavirus-battle/

This is Shortwave Radiogram in MFSK64 Please send your reception report to radiogram@verizon.net This week's images ...

Figure 2. A surgical mask on the Fearless Girl statue outside the New York Stock Exchange, 19 March. From bit.ly/2UjWtQH

Figure 3. This bear on a cold night in Romania demonstrates why social distancing is a good idea. From bbc.in/2vPSMbX

Figure 4. A closeup of a damselfly in China, looking like a Chinese painting. From bbc.in/2vPSMbX

Figure 5. A pedestrian looks at an illuminated map board in the empty streets of the Alpine resort of Zermatt, Switzerland, amid the spread of the COVID-19, 18 March. From bit.ly/39jifbr

Figure 6. Father Scott Holmer of St. Edward the Confessor Catholic Church in Bowie, Maryland, hears confessions in the parking lot of the church that remains closed because of restrictions set in place because of the coronavirus. From wapo.st/2wEzEhh

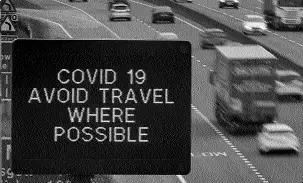

Figure 7. Coronavirus signage on the M80 motorway near Banknock, Scotland. From bit.ly/3amg4VI

Figure 8. A family in Rome, 12 March. From bit.ly/2UjWtQH

Our painting of the week is "Coconut Palms' Last Stand, Key Biscayne" by Paul Hampton Crocket. From bit.ly/2UA8fVO …

Sending Pic:207x154C;

Shortwave Radiogram returns to MFSK32 ... Before RSID: <<2020-03-29T08:28Z MFSK-64 @ 1422100+1499>> This is Shortwave Radiogram in MFSK32 ... Shortwave Radiogram is transmitted by: WRMI, Radio Miami International, wrmi.net and WINB Shortwave, winb.com Please send reception reports to radiogram@verizon.net And visit http://swradiogram.net Twitter: @SWRadiogram or twitter.com/swradiogram I'm Kim Elliott. Please join us for the next Shortwave Radiogram.